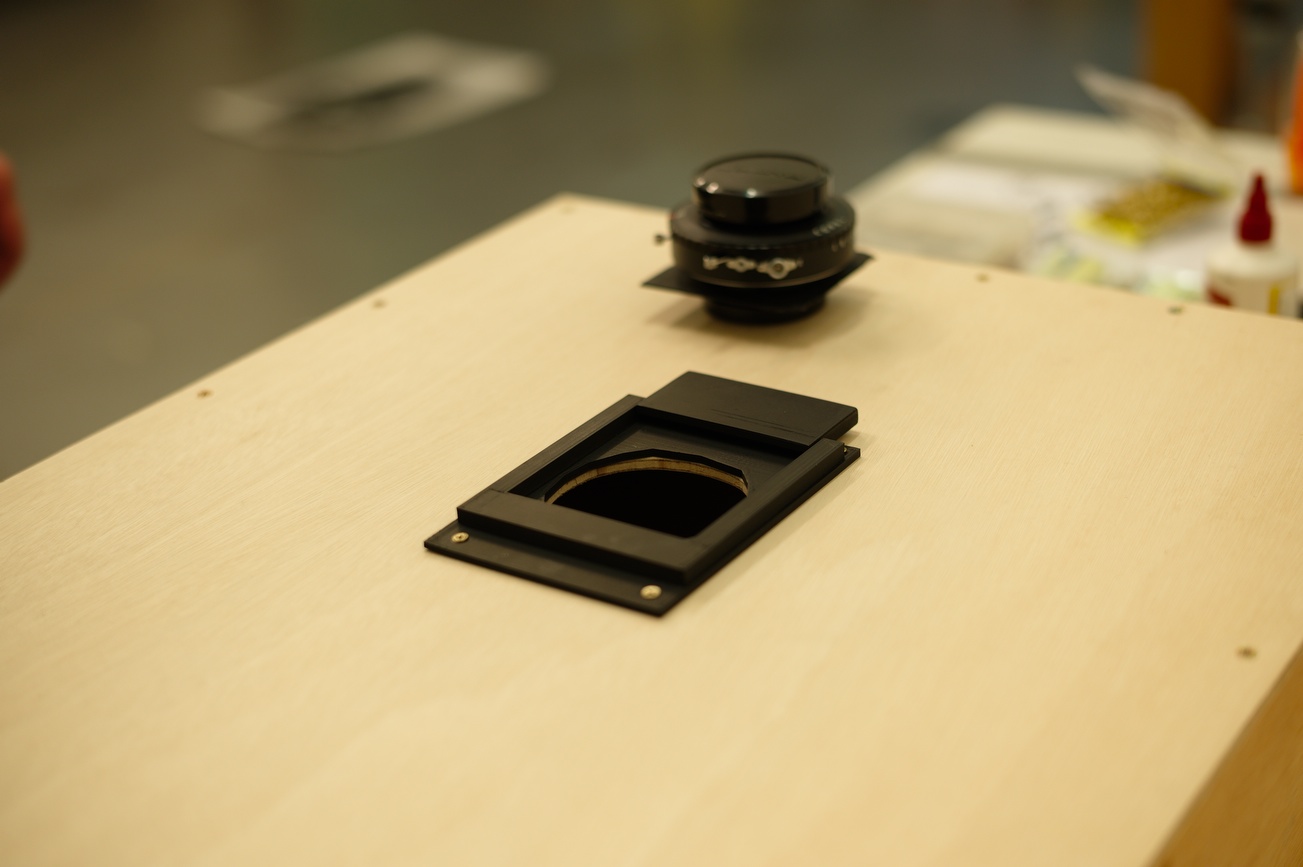

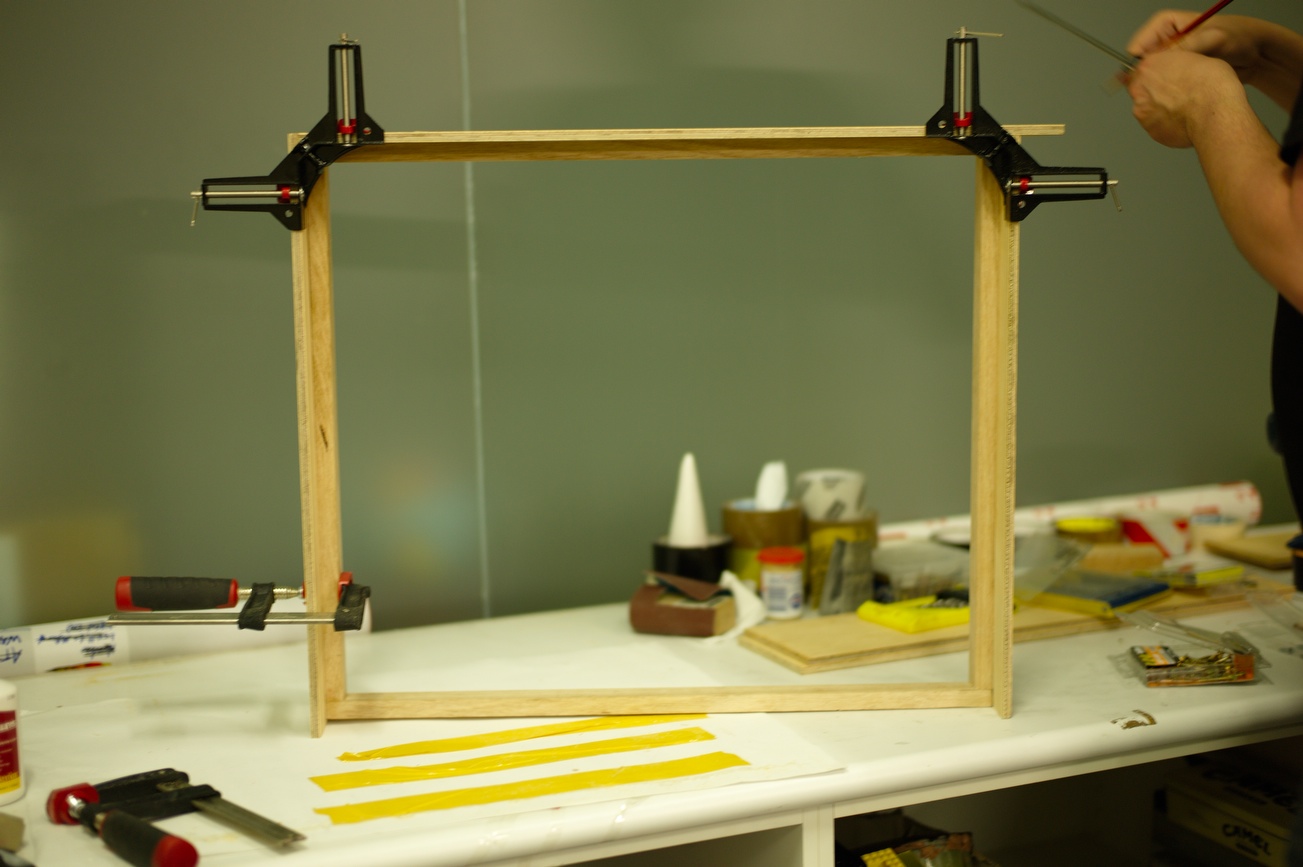

We’ve made some progress on our build of a 20×24″ view camera. We put together the foam-core bellows using a healthy amount of matte gaffer tape, and did a test fit to the front and back standards. We started putting together the PVC pipe extension rail system, and we’ve got a whole host of small issues that will need addressing as the camera progresses. Excited about the prospect of having a working view camera, we attached the Fujinon-C 600mm lens to a piece of foam-core using the remaining gaffer tape, and made a makeshift ground glass from six sheets of tracing paper taped together, and had ourselves a proof-of-concept working 20×24 view camera! Some shots below (please excuse the focus/exposure of these snapshots!);

Read more about the development of the camera in here.

Testing the fit of the foam-core bellows

Testing the fit of the foam-core bellows

Looking through the camera from the incomplete front standard (yet to have a front face)

Our makeshift ground glass made from tracing paper

Looking through from the front of the camera to our makeshift ground glass made from tracing paper at the back…

Our half finished 20×24 camera sitting on a table on wheels (makes a nice stand!), sitting ready to test out the lens…

View of the temporary foam-core front standard with Fujinon-C 600mm lens – hastily taped together from some foam-core offcuts!

Piotr posing in front of the 20×24 camera

View from the back of the camera – Piotr’s image appears upside-down on the tracing paper ground glass on the back of our 20×24 camera – it works!

Piotr’s image appears upside-down on the tracing paper ground glass on the back of our 20×24 camera – it works! (Detail)

My turn to pose in front of the DIY 20×24 camera

With an expression somewhere between serious and quizzical, I appear upside-down on the tracing paper ground glass on the back of our 20×24 camera. You can’t tell, but I’m very happy with our progress so far!